Update Feb. 1, 2016: The class decided to built a Flexyhand after first trying out a Cyborg Beast. They encountered many issues with printing but still met their goal to deliver a final product. They still hope to connect with a recipient.

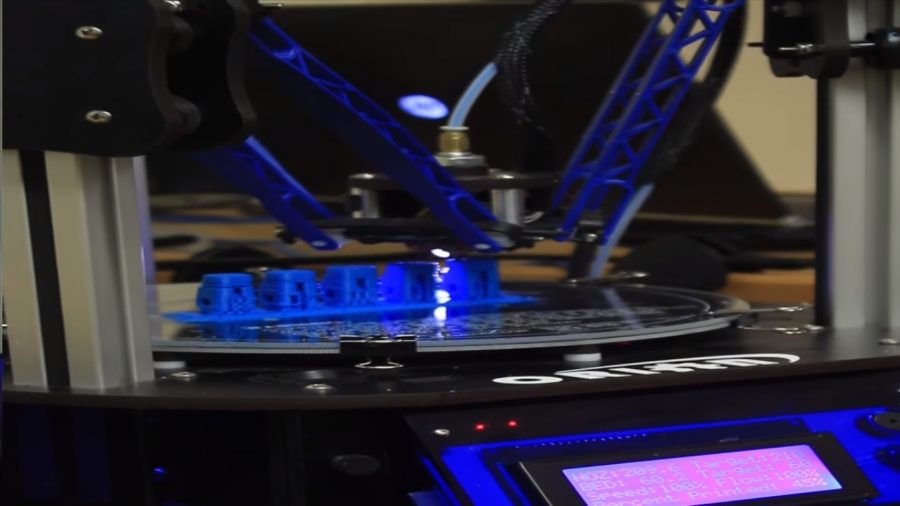

It started with an article, a 3-D printer, and a dream. A student came into Luis Rodriguez’s Computer Aided Design V classroom with an article from Parade Magazine and told him about a printable prosthetic hand. Rodriguez responded, “Let’s try it.”

Almost a year later, the current CAD V class is adapting a hand design to print in 3D and give to a child in need. It is the perfect marriage of 3D modeling practice and community outreach. “It brings out that humanitarian aspect that you don’t cover in any curriculum,” said Rodriguez.

At the helm of this project are six CAD V students, split into two teams. One is adapting the tried-and-true Cyborg Beast model; the other is customizing the newer and more experimental Flexy-hand. Although they are taking two different approaches, the end goal for each team is the same. “We are going to try to help someone out in the process of expanding our CAD knowledge,” said senior Harry Randazzo, a member of the team working on Flexy-hand.

The difference between the designs is simple: one is a robust, practical hand and the other is a more streamlined, lifelike prototype. The teams will be developing each design and the class will ultimately choose to go forward with whichever proves more effective.

The purpose of creating the hand is to aid those who suffer from Amniotic Band Syndrome, a condition that occurs when amniotic string-like bands cut off blood flow to limbs and cause birth defects. This may appear as missing fingers or underdeveloped hands.

For many families seeking prosthetics for an afflicted loved one, it can be difficult or even impossible to find a factory manufactured hand that is not astronomical in cost. Sometimes, a traditional prosthetic hand can cost up to $60,000. This is where the CAD V teams and their 3D models come in. “The beauty of it is that it costs about $11 for us to print instead of $30,000 for someone to buy,” said Rodriguez.

CAD V is demonstrating what can happen when schools merge learning with the real world; even high school students can make a profound difference in another person’s life. According to Rodriguez, it wouldn’t be possible without skilled, specialized students to do the job. “Not just anyone can do this; the students have come up through the courses and it’s a lot of upperclassmen working on this,” he said. It goes to show you that sometimes the best way to create positive change is to simply lend a helping hand.

Additional Information

CAD V is aiming to have a polished final design and a recipient by January.

The legal team of SPFHS has drafted a release “stipulating the purpose of hand,” in order to make sure that the recipient does not misuse the hand and get injured. Any delays to the timeline set by Mr. Rodriguez would likely result from the need for more legal documentation.

The class is currently looking for a recipient. They are reaching out to local Children’s Hospitals in Mountainside and New Brunswick and inquiring in the online community at e-NABLE.

If you or someone you know would be interested in potentially being a recipient, contact The Fanscotian.